Aluminum extrusions are fundamental components across numerous industries, from automotive and construction to electronics and aerospace. The quality, precision, and efficiency of these profiles directly impact the final product’s performance and cost.

When seeking a supplier for aluminum extrusions services, businesses must look beyond mere production capability. The choice of a manufacturing partner is a strategic decision that affects supply chain reliability, material innovation, and compliance with strict industry standards.

A careful evaluation of a supplier’s core competencies, from design support to quality assurance, is essential for securing a successful, long-term manufacturing relationship.

Design and Engineering Support Capabilities

The effectiveness of an extruded profile often begins with its design. A top-tier provider of aluminum extrusions services should offer robust technical and engineering support.

This includes expertise in material science to recommend the correct alloy (such as 6061 or 6063), and advanced computer-aided design (CAD) capabilities to optimise the profile for both performance and manufacturability.

Look for a partner who can provide design-for-manufacture (DFM) advice, helping you minimise wall thickness, reduce material usage, and ensure the profile can be extruded efficiently without compromising structural integrity. Their ability to collaborate on complex, custom shapes is a significant competitive advantage.

Tooling, Die Manufacturing, and Maintenance

The quality of the extrusion die is paramount, as it directly determines the final product’s precision and surface finish. Inquire about the provider’s in-house tooling capabilities.

A supplier that designs, manufactures, and maintains its own dies typically offers faster lead times for prototypes and better control over quality. Assess the material and precision of their dies, as well as their maintenance program.

A consistent maintenance schedule is necessary to prevent die wear, which can cause dimensional variations in the aluminum extrusions over a production run, leading to costly quality control issues.

Quality Assurance and Certification Standards

Quality control should be non-negotiable. The chosen provider of aluminum extrusions services must adhere to strict international quality management standards, such as ISO 9001.

Depending on your industry, specific certifications—like AS9100 for aerospace or IATF 16949 for automotive—may be required.

Ask about their inspection protocols, including dimensional checks, material testing, and surface finish assessment.

They should provide a clear process for handling non-conforming materials and offer full traceability of materials, from the billet source through to the final finished product.

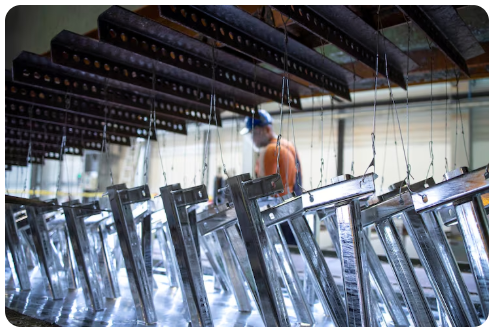

Secondary Processing and Value-Added Services

Many projects require profiles that are not just extruded, but also cut, machined, or finished. A comprehensive supplier should offer a range of secondary processing capabilities. These value-added services might include precision cutting, CNC machining, drilling, punching, and welding.

Furthermore, inquire about their finishing options, such as anodising (for corrosion resistance and aesthetics), powder coating (for durability and colour), or painting.

Consolidating extrusion and post-processing with a single source streamlines your supply chain and maintains accountability for the final quality of the aluminum extrusions.

Production Capacity and Lead Time Reliability

Evaluate the supplier’s production capacity against your volume requirements and growth forecasts. A reliable partner should be able to scale production quickly without sacrificing quality. Ask for clear, verifiable data on their typical lead times, from die creation to final delivery.

Reliability in meeting deadlines is crucial for maintaining your own production schedules. Furthermore, assess their logistics and warehousing capabilities to ensure they can manage inventory and just-in-time (JIT) deliveries smoothly and consistently.